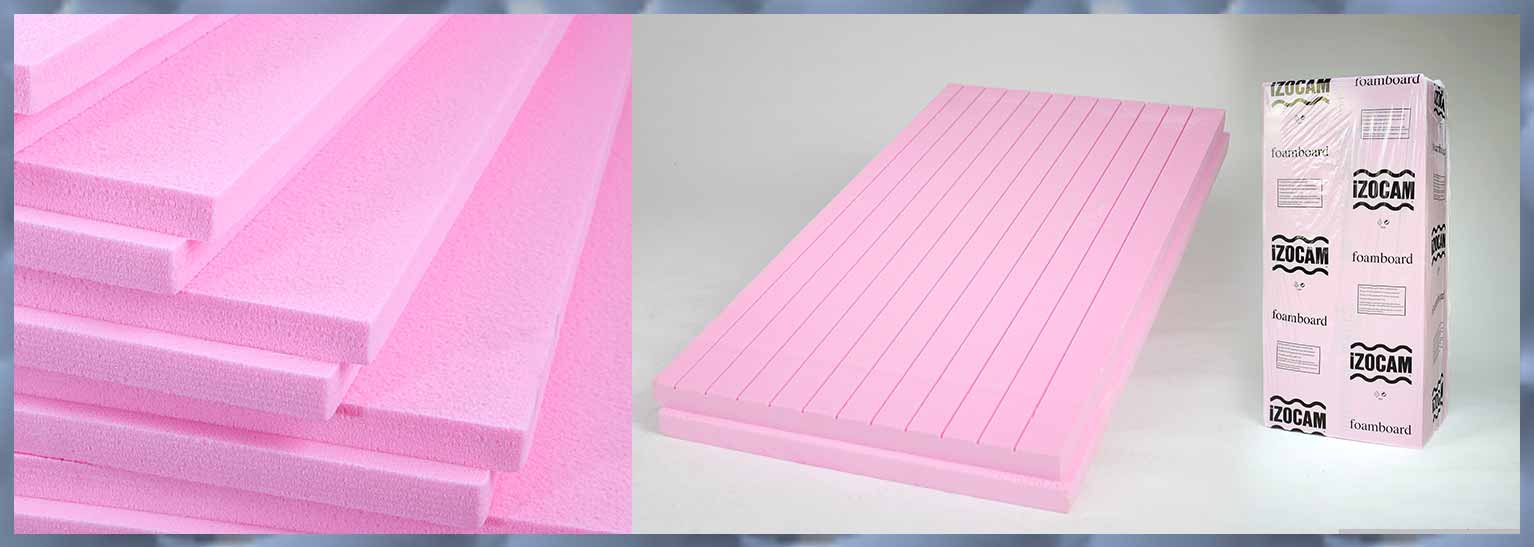

Extruded Polystyrene (XPS) FOAMBOARD

Extruded Polystyrene (XPS) FOAMBOARD

Extruded polystyrene is produced from polystyrene, by extrusion. It can be manufactured in the form of board in different size, edge and surface shape and with different compressive strength, according to the intented use and the place of use. It is used for thermal insulation.

Extruded Polystyrene (XPS) FOAMBOARD

- Extruded polystyrene is produced from polystyrene, by extrusion.

- It can be manufactured in the form of board in different size, edge and surface shape and with different compressive strength, according to the intented use and the place of use.

- It is used for thermal insulation.

- It is produced in the plants that hold the ISO 9001 Quality Management System, ISO 14001 Environmental Management System, OHSAS 18001 Occupational Health & Safety Management System and ISO 50001 Energy Management System certificates provided by Bureau Veritas.

- Izocam Foamboard products that are subject to TS 11989 – 1 EN 13164, hold the CE mark according to the Construction Products Directive (305/2011/AB).

- Its declared thermal conductivity is λ ≤ 0,035 W/mK. (at 10˚C)

- Depending on the declared thermal conductivity values, Izocam Foamboard products are in the thermal conductivity group of 030 and 035.

- Water vapour diffusion resistance factor μ = 90 – 100.

- The temperature of use is between -50/+75˚C.

- It has 100% closed porous cell structure that keeps the water out.

- It does not have a capillary absorbency.

- It has high compressive strength.

- Even though it is resistant to acidic and basic chemicals, it is sensitive to chimney gases, methane group gases and chemicals of gasoline group, eter, esther and amine group.

- It is sensitive to ultra violet (UV) rays of the sun. It should be protected from direct sun light.

- It is classfied as “E” with respect to TS EN 13501-1.